When determining what type of valve you need for a specific application, it’s important to know which kind of valve actuator your project requires.

In an automated valve assembly, the actuator is the component that causes the valve to open or close. Valve actuators can be triggered by electricity, hydraulic pressure or air (pneumatic) pressure. Although single-acting hydraulic and electric actuators do exist, the term single-acting is most commonly used to describe pneumatic actuators.

Commonly referred to as spring-return actuators, a single-acting pneumatic actuator uses air to open the valve and a mechanical spring (or springs) to close the valve. The actuator can also be configured inversely so that air closes the valve and the spring is used to open the valve; this is called a normally-open configuration.

The most common reason single-acting actuators are chosen is for their reliable fail-safe design. This means that if power or air pressure is lost, the valve will quickly move to the normal position. This is useful in applications where serious consequences may occur if the valve remains open (or closed) when power and/or air pressure is lost.

Three drawbacks to single-acting actuators are:

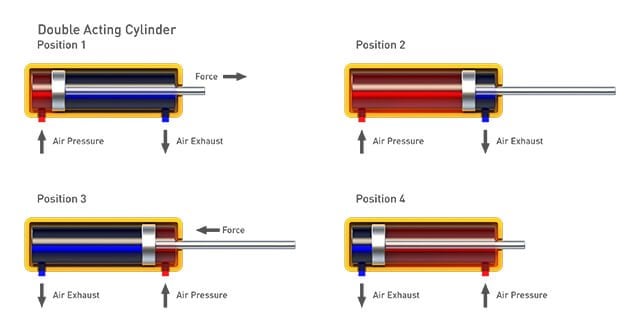

Unlike single-acting actuators, double-acting actuators use air pressure to both open and close the valve.

This is the most popular style of pneumatic valve actuator. Double-acting actuators are selected for their lower cost and superior longevity, since the absence of mechanical springs in most models eliminates the least durable component in the actuator. It is not uncommon for a high-quality double-acting actuator to cycle millions of times before failing.

Single acting actuators are common in low to moderate cycle applications where the valve failing in the wrong position could present a serious safety hazard and/or cause damage to nearby equipment. If power or air pressure is lost, single-acting actuators ensure that the valve will fail to the normal position. For this reason, single-acting actuators are the best choice when the simplicity and reliability of a safety system are of the utmost concern.

Double-acting actuators are ideal for high cycle applications and/or applications where the valve failing to the closed (or open) position when power is lost does not present a critical issue. Double-acting actuators are the most popular choice for their lower cost and superior longevity. Double-acting actuators are also more compact than single-acting actuators and may be the only option in small form factor applications.

Gemini Valve now offers an industry-first double-acting pneumatic actuator with failsafe. This actuator combines the durability of a double-acting actuator with the failsafe normally only offered by spring-return models. The actuator operates in a double-acting configuration until power or air pressure is lost and the springs engage automatically to return the valve to the normal position.

The type of valve actuator you choose depends on your specific application. When it comes to deciding whether single- or double-acting actuators are right for your situation, the team at Gemini Valve can offer expert guidance and advice.

Vice President of Marketing

George Packard, Vice President of Marketing at Gemini Valve, has been involved in Technical Sales and Marketing in the valve industry for over 10 years. George’s varied experience includes communicating with clients to troubleshoot critical applications, and working alongside top engineers in the industry to promote the latest innovations in automated ball valve design.

A comprehensive introduction to valve actuators, covering power sources, failsafes, questions to ask and more.

A linear valve actuator is a mechanical device that transforms rotational movement into linear movement in a push/pull motion, thereby enabling valve closure components to follow a straight path to at…

Choosing the right type of valve actuator is crucial for operational efficiency.